Customized & standard Mould Base

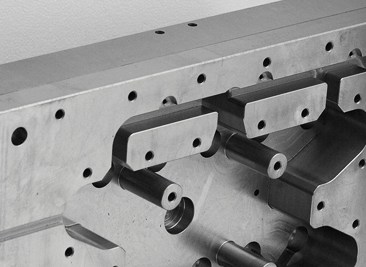

Customized Mould Base

This section introduces our KH Plates, which are high-quality steel plates specifically designed for mould bases. This product group covers plates ready for assembly into mould base. These plates are manufactured using prime-grade steel, typically C 45, to meet standard mould base requirements. However, for projects demanding exceptional performance, we can provide plates and complete mould bases made from higher-grade steel options. All edges are also machined and surface ground. All plates are then finished with operation on a precision CNC machine –‘Deckel-Maho’ imported from Germany or similar. The plates are fully inspected before dispatch.

The KH Plate program is a one-stop shop for all your mould base plate needs. It offers a wide variety of square, rectangular, flat, round, and ring-shaped plates in various sizes. These plates serve as the foundation for your mould base. To further customize and complete your mould base, the KH program is complemented by the SN product group. SN offers a comprehensive selection of parts, components, and accessories that work seamlessly with KH plates. The KH program itself boasts an impressive size range, catering to mould bases as small as 95 x 95 to 796 x 996 are available.

The KH Plate program prioritizes functionality by using C45 steel, a reliable material that fulfils the typical demands of a mould base. This keeps costs manageable. However, if your project has unique needs, we can provide complete mould bases or specific plates crafted from higher-grade steel for enhanced performance.

By specifying standard thicknesses, bore sizes, and tapping dimensions, we can effectively utilize standardized components like locating guide pillars and bushes from our SN range (details provided in respective sections).

We've created a table outlining various plate thickness options. Encouraging your design team to select mould base sizes and plate thicknesses from this table will gradually increase the demand for standard mould bases, leading to improved availability and faster production times.

The PP Plate program offers high-quality, pre-machined and ground plates without holes. These standardized plates come in various sizes and thicknesses, with the maximum dimension reaching a substantial 796 x 996 mm. This ensures consistent quality and fast turnaround times.

However, the program understands the need for customization. If you require holes on the plates, you can opt for the complementary PP Plate option. Simply provide your drawings, and we'll handle the boring and tapping. Combine these modified plates with the versatile accessories from the SN group, and you have the freedom to create a mould-base that perfectly meets your specific needs. This system provides the perfect balance: standardized production on for efficiency and quality, alongside the flexibility for designers to personalize their creations.

The PP Plate program goes beyond just standardized components. It empowers mould makers with the freedom to create custom designs through the complementary PP Plate program. PP Plates, available in the same variety of shapes (square, rectangle, flat, round, ring) as KH Plates, allow you to specify hole locations and tappings based on your unique requirements. This flexibility, coupled with the extensive selection of SN group accessories, streamlines the mould base building process, enabling faster project completion.

But the benefits extend beyond moulds. PP Plates find application in various engineering fields, including jigs, fixtures, and even the construction of specialized machinery. This program consistently saves time and labour across numerous industries.

For temporary applications like fixtures, the program offers a cost-effective option with "M" prefixed machined plates, eliminating unnecessary grinding processes.

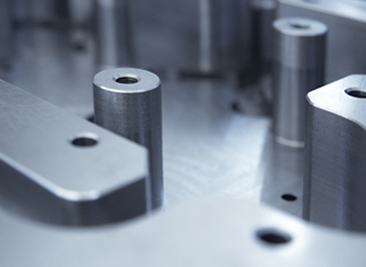

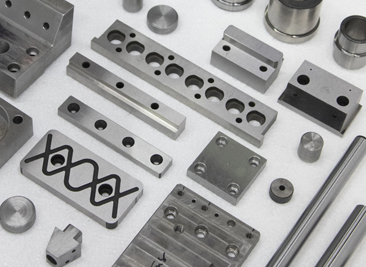

The SN Group, an integral part of the Normalien system, provides a comprehensive library of standardized components and accessories specifically designed. This program caters to a wide array of parts regularly used in mould making. From Locating Guide Pillars and Bushes to Locating Units (both flat and round), Ejector Pins, Locating Rings, and Lifting Devices, the SN Group has you covered. Each component comes in various sizes and dimensions. To further enhance your design process, By leveraging these standardized parts, you can significantly reduce design time and associated costs. This frees up valuable resources so you can focus on other crucial aspects of your project.

The SN Group prioritizes quality and performance. Each component is crafted from high-grade steel specifically chosen to match its intended use. This ensures optimal functionality and durability. For instance, high-grade case hardening steel might be used for components requiring exceptional wear resistance, while ball bearing steel provides smooth, precise movement. Hot die steel tackles high-temperature applications, while HCHC and cold working steels excel in specific demanding environments. To empower informed decision-making, most SN Group parts clearly indicate the type of steel used, its tensile strength, and hardness rating.

Furthermore, for seamless project planning and procurement, Normalien offers detailed dimension sheets for each SN product. These comprehensive resources readily outline the standardized sizes readily available from stock. To obtain a dimension sheet, simply visit our website (www.normalientooling.com) and fill out a request form. This eliminates the need for time-consuming dimension searches and ensures you have all the information required to swiftly acquire the perfect SN Group components for your project.

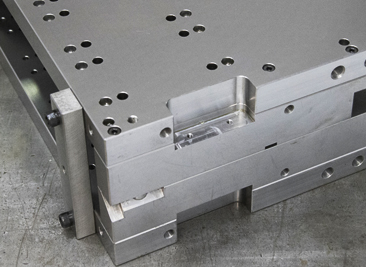

Standard Mould Base

With over 25 years of experience, Normalien has earned a strong reputation for delivering high-quality, custom-built mould bases to the industry. Our commitment to precision and timely delivery has fostered long-term partnerships with our valued customers.

Recognizing the growing demand for efficient mould production, the mould base industry emerged in Western countries approximately 80 years ago. To meet the increasing needs of a rapidly expanding industrial sector, standardized mould bases became essential. While this concept has taken root in India through individual company standards, Normalien is taking a proactive approach.

Normalien continues to produce custom-built mould base orders, but at the same time, Normalien produces Normalien Standard Mould Bases (NSMB) in three phases.

- Phase I: Offering 19 standard sizes ranging from 196x196mm to 296x696mm.

- Phase II: Expanding the range with 16 additional sizes from 346x346mm to 396x896mm.

- Phase III: Completing the series with 10 more sizes from 446x446mm to 496x796mm.

Normalien has significantly enhanced India's mould-making industry by delivering superior cost, consistency, quality, and finish. To further optimize the process, we are introducing standardisation Normalien Standard Mould Base (NSMB) program.

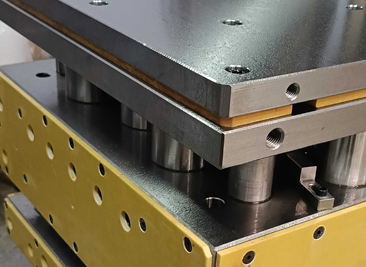

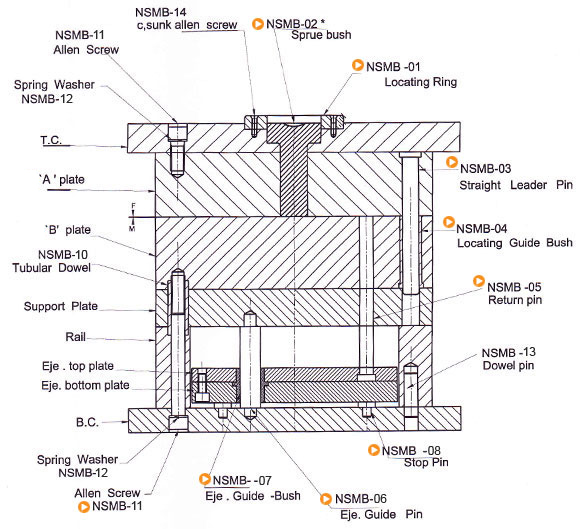

This initiative aims to drastically reduce delivery time while providing exceptional value to our customers. By maintaining a ready stock of these NSMBs, We are committed to deliver the order within 5 working days at competitive prices. Each NSMB includes:

- Precision-machined, ground, and processed C45 steel plates and rails

- Four straight leader pins

- Four locating guide bushes

- Four locating rings

- Guided ejection assembly with return pin

- Stop pin

- Comprehensive set of Allen screws, dowel pins, spring washers, and screws

We are confident that the NSMB program will be a game-changer for the mould-making industry.

The Normalien Standard Mould Base (NSMB) program offers significant benefits in terms of quality, delivery time, and cost-effectiveness:

Superior QualityConsistent Precision: Mass production techniques enable us to achieve tighter tolerances and improved overall quality.

Enhanced Reliability: Our standardized components undergo rigorous quality control, ensuring superior performance.

Rapid DeliveryAccelerated Production: NSMB orders are typically fulfilled within 6 days, compared to the industry average of 18-20 days for custom-built mould bases.

Reduced Time-to-Market: Faster delivery times contribute to quicker product launches and increased market competitiveness.

Cost EfficiencyOptimized Pricing: The economies of scale associated with mass production allow us to offer NSMB's at competitive prices.

Reduced Inventory: By utilizing standardized components, mould makers can streamline their inventory management.

Design FlexibilityWhile NSMB's are standardized, they offer flexibility in mould design. Customers can select from a range of standard plate thicknesses, bottom plates, support plates, core/cavity plates, and rails to meet their specific requirements.

Customization OptionsFor specialized needs, Normalien can provide additional services such as drilling, machining pockets, and incorporating cooling channels. These custom modifications may incur extra costs and extend delivery times slightly.

By adopting the Normalien Standard Mould Base program, mould makers can benefit from higher quality, faster delivery, and cost savings without compromising design flexibility.

| SR NO | CODE NO | SIZE IN MM |

App SIZE IN INCH |

TC | BC | SUPP |

Eje Top |

Eje Bottom |

A & B PLATE THICKNESS IN MM | RAIL HEIGHT IN MM | ||

| L | M | D | E | |||||||||

| 1 | NSMB 1919 | 196 X 196 | 8X8 | 36 | 22 | -- | 26 | 36 | 12 | 17 | 22,26,36,46,56,66,76 MM | 46,56,76 |

| 2 | NSMB 1924 | 196 X 246 | 8 X 10 | 36 | 22 | -- | 26 | 36 | 12 | 17 | 22,26,36,46,56,66,76 MM | 46,56,76 |

| 3 | NSMB 1929 | 196 X 296 | 8 X 12 | 36 | 22 | -- | 36 | -- | 12 | 17 | 22,26,36,46,56,66,76,86,96 MM | 56,76,96 |

| 4 | NSMB 1934 | 196 X 346 | 8 X 14 | 36 | 22 | -- | 36 | -- | 12 | 17 | 22,26,36,46,56,66,7686,96 MM | 56,76,96 |

| 5 | NSMB 1939 | 196 X 396 | 8 X 16 | 36 | 22 | -- | 36 | -- | 17 | 22 | 26,36,46,56,66,7686,96 MM | 56,76,96 |

| 6 | NSMB 2424 | 246 X 246 | 10 X10 | 36 | 22 | -- | 36 | -- | 12 | 16 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 7 | NSMB 2429 | 246 X 296 | 10 X 12 | 36 | 22 | -- | 36 | 46 | 12 | 16 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 8 | NSMB 2434 | 246 X 346 | 10 X 14 | 36 | 22 | -- | 36 | 46 | 16 | 22 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 9 | NSMB 2439 | 246 X 396 | 10 X 16 | 36 | 26 | -- | 36 | 46 | 16 | 22 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 10 | NSMB 2444 | 246 X 446 | 10 X 18 | 36 | 26 | -- | 36 | 46 | 16 | 22 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 11 | NSMB 2449 | 246 X 496 | lOX 20 | 36 | 26 | -- | 36 | 46 | 16 | 22 | 26,36,46,56,66,76,86,96,106MM | 56,76,96 |

| 12 | NSMB 2929 | 296 X 296 | 12 X 12 | 36 | 26 | 36 | 36 | 46 | 12 | 17 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 13 | NSMB 2934 | 296 X 346 | 12 X 14 | 36 | 26 | 36 | 36 | 46 | 16 | 22 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 14 | NSMB 2939 | 296 X 396 | 12 X 16 | 36 | 26 | 36 | 36 | 46 | 16 | 22 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 15 | NSMB 2944 | 296 X 446 | 12 X 18 | 36 | 26 | 36 | 36 | 46 | 16 | 22 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 16 | NSMB 2949 | 296 X 496 | 12 X 20 | 36 | 26 | 36 | 36 | 46 | 16 | 22 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 17 | NSMB 2954 | 296 X 546 | 12 X 21.5 | 36 | 26 | 36 | 36 | 46 | 16 | 22 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 18 | NSMB 2959 | 296 X 596 | 12 X 24 | 36 | 26 | 36 | 36 | 46 | 22 | 26 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| 19 | NSMB 2969 | 296 X 696 | 12 X 28 | 36 | 26 | 36 | 36 | 46 | 22 | 26 | 36,46,56,66,76,86,96,106,116MM | 56,76,96 |

| I ITEM---CODE | DESCRIPTION | QTY |

| NSMB - 01 | Locating Ring | 1 NO |

| NSMB - 02 | Sprue Bush (Plain) Sprue Bush ( 'A' series) Sprue Bush ('B' series) |

1 NO |

| NSMB - 03 | Straight Leader Pin | 4 Nos |

| NSMB - 04 | Shoulder Bush | 4 Nos |

| NSMB - 05 | Return Pin | 4 Nos |

| NSMB - 06 | Ejector Guided Pin | 4 Nos |

| NSMB - 07 | Ejector Guided Bush | 4 Nos |

| NSMB - 08 | Stop Pin | 4 Nos |

| NSMB - 09 | Locating Unit ( Round) with spacer | 4 Nos |

| NSMB - 10 | Tubular Dowel (Std Item) | 2 Nos |

| NSMB - 11 | Allen Screw (Std Item) | 12 Nos |

| NSMB - 12 | Spring Washer (Std Item) | 8 Nos |

| NSMB - 13 | Dowel Pin (Std Item) | 4 Nos |

| NSMB - 14 | Flat Head Countersunk Allen Head (Std Item) |

2 Nos |

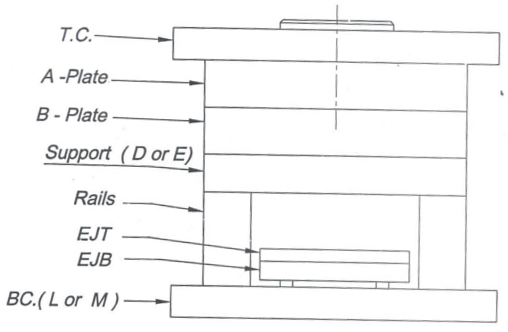

Please refer to cross section drawing of Normalien Standard Mould Base and table no. 1

In our system, your Tool Designer, has a wide choice of thickness in BC, with symbols 'R' & 'S', in support plate with symbols 'D' & 'E'. Further cavity and core plates 'A' & 'B', plates have wide choice of thickness to select the most appropriate thickness for the tool being designed. The last figure in bracket is the height of rail.

Normalien employs a careful selection of steels for its mould base and component production. While C45 steel is the standard choice for plates, higher-grade options like P20 steel are also available to suit specific requirements. Many components are crafted from case-hardening steel, primarily SAE 8620 (equivalent to 16mm Cr5 German grade). A detailed analysis of these steel grades is provided below.

Chemical Composition| Sr. NO | Material | C | Cr | Ni | Mn | S |

| 1 | C45 | 0.45/0.50 | - | - | 0.6/0.9 | 0.024 |

| 2 | P20(1.2311) | 0.40 | 1.90 | - | 1.5 | - |

| 3 | SAE 8620 | 0.18/0.23 | 0.35/0.65 | 0.40/0.70 | 0.60/1.10 | - |

| Sr. NO | Material | Kg./mm2 | Elongation% | Hardness BHN | Additional |

| 1 | C45 | 60 | 11 | 210 max | - |

| 2 | SAE 8620 | - | - | - | - |

| Sr. No | ASTM | C | Si | Mn | S | Cr | Mo | Ni |

| 1 | P20 - DIN -1.2311 | 0.4 | 0.3 | 1.5 | 1.9 | 0.2 | ||

| 2 | P20 - DIN -1.2312 | 0.4 | 0.3 | 1.5 | 0.07 | 1.9 | 0.2 | |

| 3 | P20 - DIN -1.2738 | 0.4 | 0.3 | 1.5 | 2 | 0.2 | 1.1 | |

| 4 | P20 - DIN -1.2085 | 0.3 | 0.35 | 1.4 | 0.1 | 16 | 0.2 | 0.6 |